Justin Mason: I’m part of the Microvellum User Advisory Group – you guys are so kind as to let me help. Microvellum: Why is it that you have a Beta version? I also have the R3 release in Beta, which I have tested quite a bit and have run a few projects through to production. Justin Mason: We run all of our live production through the Toolbox v15 R2 release.

Microvellum: What version of Toolbox are you running right now? One point to point, one nested-based auto-loading CNC and a beam saw utilizing ALIS for printing labels. Justin Mason: We have 2 CNC machines out in the shop. Microvellum: And how many different machines do you have connected with Microvellum? Justin Mason: Well, Interior Woodworking Specialists has had Microvellum since 2006, but I have been using it for about 4 years. Microvellum: How long have you been using Microvellum Software? You can draw and engineer things that all fit together and just work. We have to engineer for metal stone, glass and I really think Microvellum helps us in that way, because it’s in AutoCAD. Solid woods, plywood, veneer, reclaimed wood, plastic laminates, plexiglass. Radius, curve, arch… On a daily basis we have to work with so many different types of materials. We also do restaurants, anything from bars from bars to booths. We do a lot of retail store fixtures, display fixtures, cash POS, entry ways, and a lot of wall paneling. We do corporate TI, which includes casework, reception desks, wall paneling. Justin Mason: Well, the majority of our business comes from commercial projects. Can you tell us a bit more about your company? We’d like to learn about what IWS does and how you use you’re Microvellum Software. Justin Mason: Yes, I’m with Interior Woodworking Specialists, in the greater Seattle area in Washington State (United States). Microvellum: Can you tell us where IWS located again?

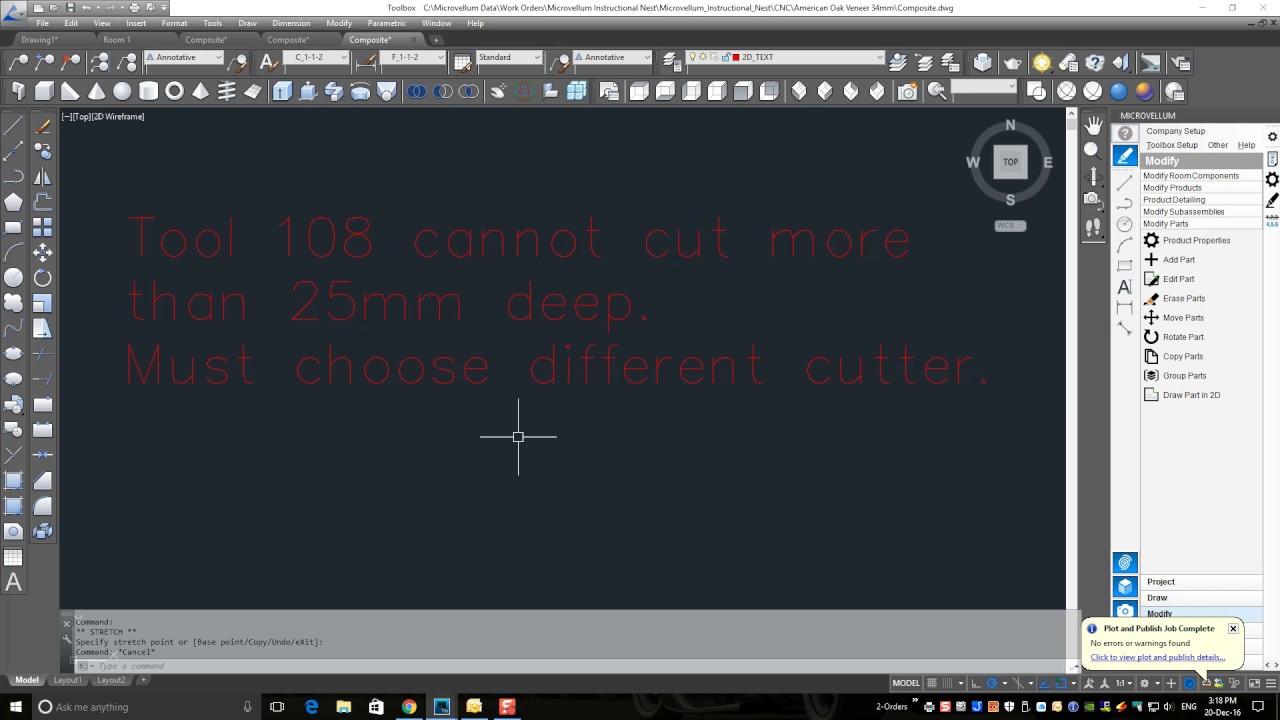

MICROVELLUM TOOLBOX 7 NESTING SOFTWARE

Justin Mason from Interior Woodworking Specialists sat in one of our recent Tech Talk events and had this to say about their Microvellum Software experience… Their slogan is, “If you can draw it, we can build it.” That is one reason their customer base is so loyal - If they say they can do, they do it. IWS works under the belief that their reputation and signature is on every piece they deliver and that’s the way they like it! IWS applies the same quality to production runs as it does to custom runs, ensuring that the inside is as strong as the outside is beautiful.

They involve all the right people and create a winning attitude that allows long term relationships to be built and maintained. They take the team approach to everything they do. The key to their success comes from running a well managed small business that supports their dedicated family of employees and includes our extended family of vendors and customers. The integrity of what they supply from the bid to the installation shows in their professional approach and their desire to supply the very best. IWS has built a staff of seasoned personnel with a reputation of broad experience, pride in craftsmanship and the ability to deliver both complicated and off the shelf solutions to our customers.

0 kommentar(er)

0 kommentar(er)